Under Tight, Over Tight, or Just Right

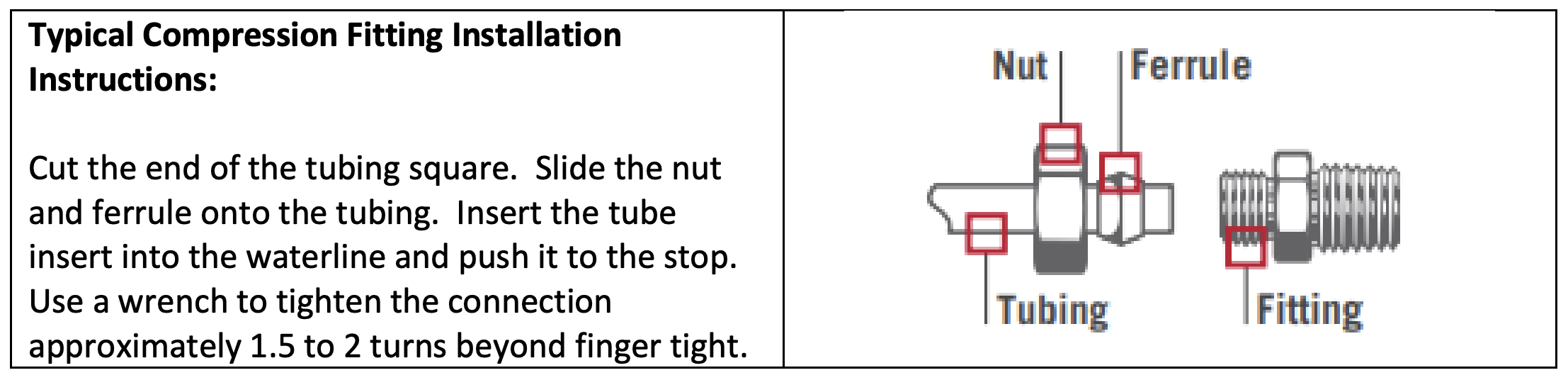

Compression fittings are common plumbing connections. One of the advantages of compression connections is that the joints are easy to assemble and disassemble. This is why these connections are often found beneath your bathroom vanity, under your dishwasher, or behind your refrigerator.

Compression connections allow do-it-yourself homeowners and plumbers to easily install various appliances and fixtures. The problem with compression connections is ensuring proper tightening. Both under-tightening and over-tightening can cause joint failure, resulting in substantial water damage and often insurance claims. Tightening the fitting requires a fine balance of torque which is crucial to the integrity of the joint. Under-tightening fails to create sufficient clamping force (generated when the ferrule is squeezed by the coupling nut), allowing the water line to pull free from the connection. Over-tightening can damage the ferrule or tubing, resulting in a leak.

In 2019 we have observed an increase in compression fitting failures installed by both homeowners and seasoned plumbers. Examining the surface of the plastic tubing located below the ferrule can provide insight into the installation.

The majority of the compression fitting failures that we have investigated this year were caused by under-tightening during installation. Some other common compression fitting installation errors include:

Using a metal ferrule with plastic tubing.

Using Teflon tape or pipe sealant when assembling the connection.

Placing the ferrule on the tubing backwards.

Failing to cut the tubing square.

So, when working with compression fittings, aim for the "just right" amount of tightening to avoid leaks and water damage to your home.